1. Structural Design

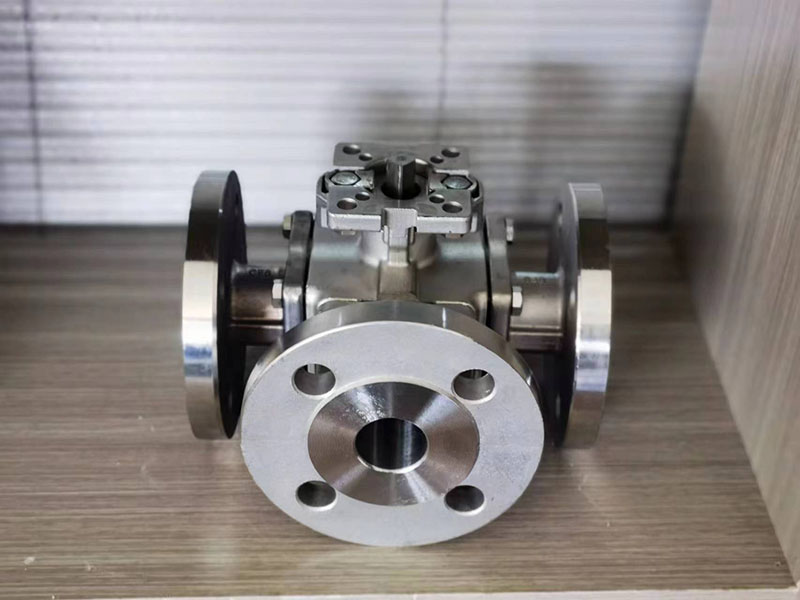

- Cube - like Body Structure: Features a compact square - body design, which is space - saving and easy to install in pipeline systems. The three - way structure with flanged ports allows for flexible connection and diversion of media.

- Stainless Steel Material: As can be seen from the figure, the valve body is made of stainless steel, providing excellent corrosion resistance, which is suitable for various media environments, such as chemical liquids, water, and gas.

- Media Diversion Control: With three flanged ports, it can realize flexible diversion, mixing, or shut - off of media. By rotating the internal ball core, the flow direction of the media can be changed, meeting the different process requirements of the pipeline system.

- Simple Operation: It can be equipped with a handle or actuator for operation. The operation is simple and convenient, and the on - site operation by personnel is easy to realize accurate control of media flow.

| Parameters | Details |

|---|---|

| Body Material | Stainless Steel (e.g., 304, 316) |

| Nominal Size | DN15 - DN100 (Common Sizes) |

| Pressure Rating | PN16, PN25 (Common Pressure Levels) |

| Temperature Range | - 20℃ - 200℃ (Depends on Sealing Material) |

| Connection Type | Flange Connection (Three - Way Configuration) |

- Chemical Industry: Widely used in chemical production lines, such as in the processes of chemical liquid mixing, diversion, and distribution. It can adapt to the corrosion of various chemical media and ensure the normal operation of the production process.

- Petroleum Industry: In petroleum refining and transportation pipelines, it can be used for media diversion and control, meeting the complex process requirements of the petroleum industry.

- Water Treatment Industry: Applicable to water treatment systems, such as in the processes of water distribution, mixing, and diversion, ensuring the efficient operation of water treatment processes.

- Design Standards: Complies with relevant national and industry standards for three - way ball valves, ensuring that the product design meets basic safety and quality requirements.

- Quality Management: Manufacturers generally have ISO 9001 quality management system certification, which ensures that the production process from raw material procurement, processing and manufacturing to product inspection is strictly controlled, and the product quality is guaranteed.

- Testing and Inspection: Undergoes strict factory tests, including pressure test (shell test and seat test), leakage test, etc. These tests ensure that the valve can operate reliably under rated working conditions and meet the requirements of pipeline system use.

- Material Certifications: For stainless steel valve bodies, relevant material certification documents can usually be provided to prove that the material meets the corresponding quality and performance standards (such as 304 stainless steel compliance with GB/T 20878 standards).